Coronavirus: could this hospital “pod” ease the medical crisis?

The first prototype of CURA is being built in Milan – an epicentre for Italy’s COVID-19 outbreak – and should be ready within weeks.

A concept to help under resourced hospitals has emerged from Italy, one of the countries that has been worst hit by the coronavirus.

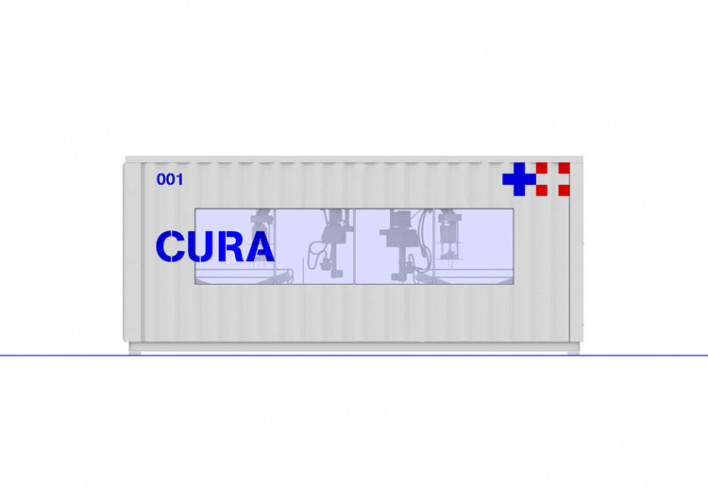

CURA, which stands for Connected Units for Respiratory Ailments, plans to convert shipping containers into intensive care unit (ICU) pods for the pandemic.

It has been developed by a range of designers and engineers who tell Design Week that a prototype should be available within three weeks.

“Biocontained” pods, connected by an inflatable structure

The CURA team says that the units “would be as fast to mount as a hospital tent, but as safe as an isolation ward”. That’s thanks to “biocontainment and negative pressure”. Biocontainment is when pathogens, such as viruses are contained by isolation in a secure environment – in this case, through the use of extractors.

Shipping containers have been chosen as the skeleton as they can be easily transported across the country, re-used in different countries and adapted “to the needs and capacity of the local healthcare infrastructure”.

Each pod is 20-foot long, and works autonomously. They can be connected by in a modular configuration with an inflatable structure. The pods could be placed near hospitals, in car parks for example, or else form “self-standing field hospitals”.

Who designed CURA – and when will it be available?

The CURA team tells Design Week that it aims to have the first prototype completed in Milan in “around three weeks”. “The project is currently at its initial phase,” the team continues. “We have started working all together just around ten days ago.”

The first step was to create a “task force” of “architects, engineers, doctors, and experts in managing emergency situations”. This includes Carlo Ratti Associati (design and innovation), Humanitas Research hospital (medical engineering), Policlinico di Milano (medical consultancy), Jacobs (master planning and logistics). Individuals include Alex Neame of Team Rubicon UK (logistics), Ivan Pavanello of Projema (engineering) and Maurizio Lanfranco of Ospedale Cottolengo (medical consultancy).

The visual identity was also a joint effort; studio FM Milano was responsible for the visual identity and graphic design and Squint/Opera created the digital media for the project. The design has been sponsored by UniCredit, an Italian bank.

Italy’s coronavirus crisis

The sheer range of contributors shows the scale of the problem, and also the shift in focus for the design companies who would usually be busy preparing for Milan’s Salone del Mobile right now. The annual design festival has been postponed from April to June amid the coronavirus outbreak.

Almost 7,000 people have died from the virus in Italy, meaning that the stakes are high. The team says that it will start to look up ways to scale up production of the pods “immediately” after the first prototype is built. It’s being developed in a warehouse in Turin, a city not far from Milan.

CURA also aims to find a solution for the problem of emergency responses to the pandemic. While building prefabricated bio contained wards is the ideal, it is time and resource intensive. The alternative, such as tents, “expose medical professionals to a higher risk of contamination and adds operational strain”.

What medical equipment is needed to treat coronavirus?

Each pod would contain enough medical equipment for two patients, including ventilators and IV stands. If these pods were to be produced in the UK, where that equipment would be found is another complicated issue. In the UK, there is a shortfall in the number of ventilators for COVID-19 patients. It is expected that the country might need 30,000 and the NHS has 8,000.

As a way to meet this need, the government met with manufacturers to discuss how they could help build ventilators. Dyson announced that it had designed its own ventilator, CoVent, and that the government had ordered 10,000 of the product. It is expected to pass through the usual phases of medical regulation and safety checks more quickly than usual, given the circumstances.

Open source design

While the design industry has rallied to find solutions for the coronavirus outbreak, there have been some questions around regulation – as open-source platforms sprung up, such as Facebook group where designers and engineers shared plans for medical equipment. CURA is open-source – meaning that anyone can download the design system or contribute suggestions – the technology complies the standards of Airborne Infection Isolation Rooms (AIIRs).

It also “follows the standards for COVID-19 hospitals issued by the Chinese authorities”. During the height of coronavirus in the Chinese city of Wuhan – where the virus first spread – two hospitals were built in two weeks, which were able to house 2,600 patients. The hospitals were closed earlier this month as it was reported that coronavirus cases were declining.

In the UK, which has recently ramped up measure in an attempt to ‘flatten the curve’ of COVID-19, it was announced that London’s ExCel Centre would become a temporary hospital. NHS Nightingale – which should be ready to use from next week – will initially house 500 beds with medical equipment. Its capacity will continue to increase, with a potential of thousands of beds to be made available.

“Under these exceptionally challenging circumstances, the NHS is taking extraordinary steps to fight coronavirus,” NHS chief executive Sir Simon Stevens said. “This will be a model of care never needed or seen before in this country.”

Great instant design thinking reusing or recycling shipping containers,

Let’s see more in uk with built in breathing tech and smaller self isolation hospitals.

prototype ?

More use shipping containers in recycling circular economy…